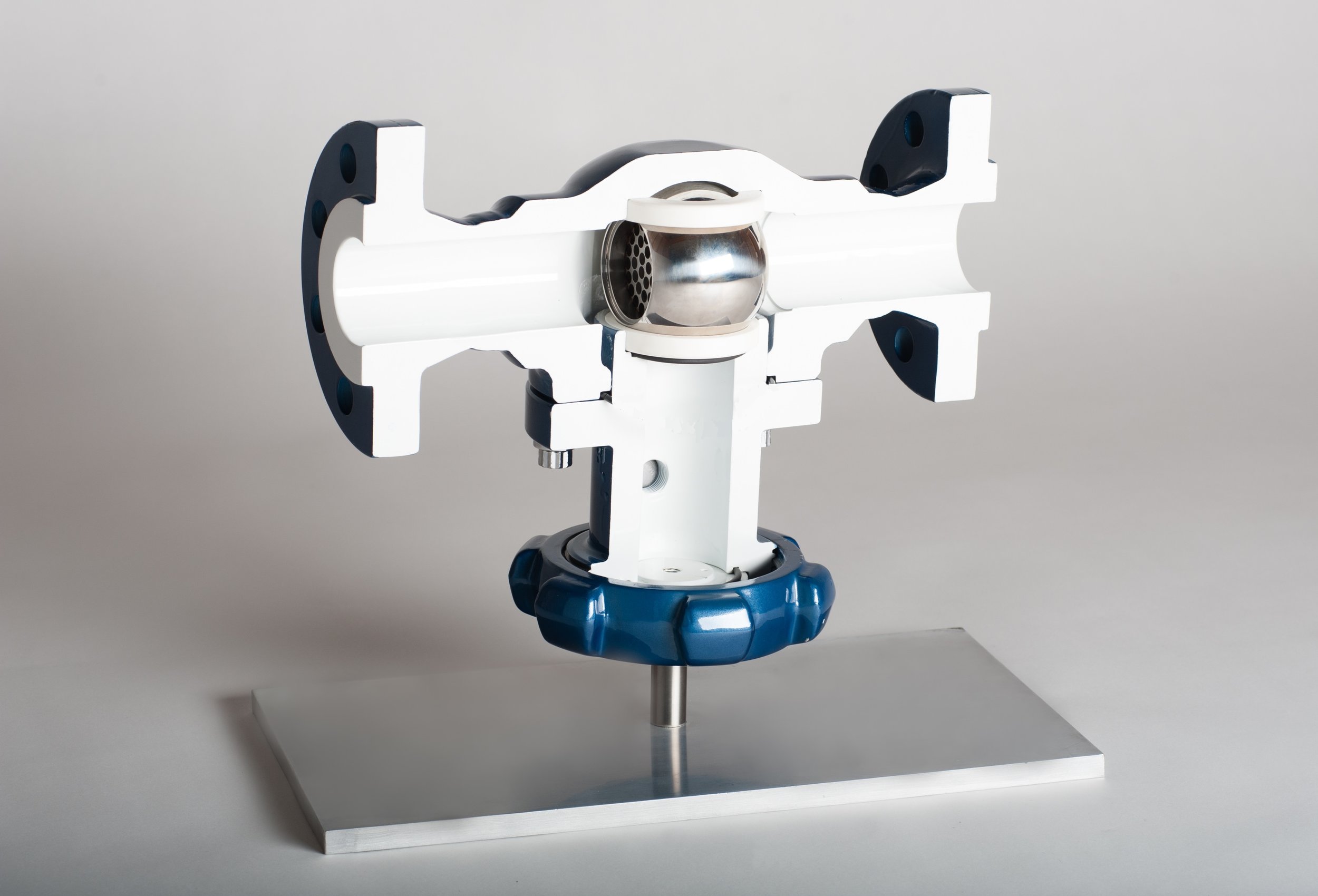

Pig Valves

Pig valves are important components of pipelines across the globe. Frontier Valve produces them in a variety of sizes and pressure ratings, designed to meet your project’s standards.

FEATURES

- The valve stem is blow out proof due to the stem being installed through the body cavity therefore being retained by the body. A self-lubricating stem thrust washer is utilized to reduce friction.

- Valve ball is made from 300 series stainless steel to resist corrosion from the fluid.

- Valve seats are manufactured from self- lubricating Delrin to minimize turning torque and provide for high pressure service applications.

- Two bleed valve connections are provided to provide for vent mounting in the best location.

- Pressure vent arrangement ensures pressure is not trapped in the pig chamber.

- Total valve servicing may be performed without special tools. Bypass style valves are field serviceable without removal from the flow line.

- Bypass style eliminates the possibility of line over-pressurization. From being shut during the pigging operation.

- Shut-off style is of double block and bleed configuration which isolates the body cavity from the flow line in both the open and closed position

- Field convertible from launcher to receiver or vice-versa.

- Launching/receiving operations are performed quickly and safely.

Bypass

The bypass style allows for continuous flow in all valve positions by isolating the chamber from the flow line which does not close the flow line. This style is utilized where the flow cannot be interrupted during the pigging operation. The bypass is integral in the valve body and provides 35% flow capacity to minimize pressure drops during the pigging operation.

Design Characteristics

The bypass pigging valve was developed to allow for minimal operations during pig launching and receiving making the operation safe and convenient. The valve pig chamber is isolated from the flow line in the normal position by the ball and seat. The benefit of having this seating configuration and the flow cavity around the exterior of the ball allows for a reduction in flow capacity without shutting off the flow line completely during the injection or receiving operations.

The valve design of the valve allows for loading and unloading of the pig chamber while the valve is in the normal flowing position minimizing the flow restrictive time when in the launching or receiving positions.

Shut-off style

The shut-off style valve utilizes seats in line with the flow path providing a double block and bleed function to isolate the flow line and eliminate the requirement for additional shut-off valves. The valve isolates the body cavity and pig chamber from the flow media in both the flowing and pig loading position

Design Characteristics

The shut-off style is utilized to launch and receive pigs with minimal operation while providing the dual function of working as a Ball Valve to provide shutoff.

Options

- Valve material trims are available for standard service, sour service per NACE MR0175, low temperature service (-50F) with special construction materials are available on request.

- All common valve end connections are available as required.

- Bypass style with internal pressure equalizing valve between the flow line and pig chamber to minimize operating torque.

- Bypass style with a spring loaded injector to push pig into the flow line to allow valve with the pig chamber facing vertically down.

Whatever your needs, we can design and fabricate a custom valve solution to meet them. Contact us today to get started.